All rights reserved. © 2015 EVTech.

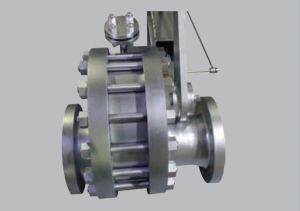

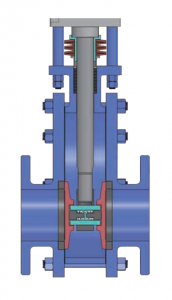

DISC VALVE

The disc valve is a valve that has a metal-to-metal sealing surface and works in rotating shearing mode.

It is particularly suitable for on/off and throttling both applications for abrasive media or slurry entrained particles.

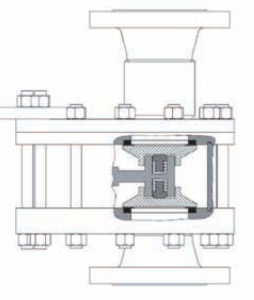

The actuator drives the stem to rotate at a certain angle to move the disc in full open, full close and middle positions.

The disc is constantly in contact with the seat through force loaded by coiled springs. These springs allow the disc to move vertically is better to compensate thermal expansion and contraction of the valve components also overcoming the effect of any back pressure for which it was designed and prevents particles from lodging between the sealing surfaces.

Differences between drive forces in the tangential disc and friction forces in the centre disc cause the disc to rotate on its seat as the valve cycles, thereby shearing and wiping away any process mediums that may accumulate.

This rotate helps grinding and polishing of the sealing surface of the valve continuously, which can maintain seat leakage improved in a long term.

FEATURES AND BENEFITS

- Unique rotating shearing disc: Self lapping disc, enhanced seat cleaning action, cuts through solids, longlasting tight

- The disc edge has a right angle, which can clean articles on the sealing surface and make the sealing surface clean

- The sealing surface with harden surface treated is highly resistant to erosion, high temperature, and abrasive working conditions.

- The sealing band surface on the seat is widened so that the force on the sealing face is distributed on a larger area,

- The full port design makes the media flow freely andcauses no drop of pressure.

- Due to the rotary switch design, there is no relative vertical motion between the stem and the packing, making thevalve more suitable to work at high temperature and high pressure applications.

- The eccentric valve body design can avoid blocking and clean the inner chamber.

- Replaceable seat design: Less maintenance expense.

TEACHIIICAL PARAMETERS

EVT PROCESS VALVE (EPV)

Size: DN50-DN450

Pressure: Class150-Class2500

Body Material: Carbon Steel, Stainless Steel and other materials

Actuators: Pneumatic, Hydraulic Cylinder, Hand wheel

Configuration

- Double Disc Design

- Bi-direction flow

- Bi-directional seal

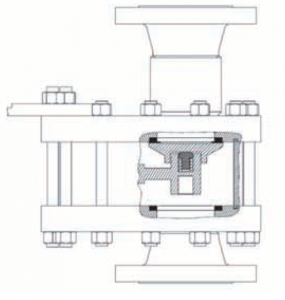

- Single Disc Design

- Bi-direction flow under specified conditions

- Uni-directional seal

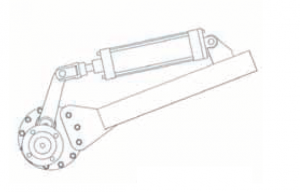

Valve Actuators

- Cylinder (Pneumatic, Hydraulic, Electric)

- Lever

- Hand wheel

IMPROVEMENT AND INNOVATION

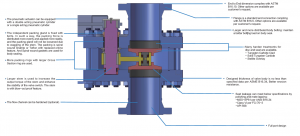

• The pneumatic actuator can be equipped with a double acting pneumatic cylinder or a single acting pneumatic cylinder.

• The independent packing gland is fixed with bolts. In such a way, the packing force is distributed more evenly and applied more stably, and the packing gland will not be loosened due to waggling of the stem. The packing is spiral wound Grahite or Teflon with replaced online feature. And Spiral wound gaskets are used for body sealing.

• More packing rings with larger Cross Section ring are used.

• Larger stem is used to increase the output torque of the stem and enhance the stability of the valve switch. The stem is with blow-out proof feature.

• The flow channel can be hardened (optional).

• End to End dimension compiles with ASTM B16.10. Other options are available per customer’s request.

Flange is a standard end connection compiling with ASTM B16.5. Other options are available per customer’s request.

Larger and more distributed body bolting: maintain a better bolting load on body seal.

• Many harden treatments for disc and seat are available. – Tungsten Carbide Clad – Solid Tungsten Carbide – Stellite Overlay

• Designed thickness of valve body is no less than specified data per ASME 816.34, Better erosion resistance.

Seat leakage can meet below specifications by polishing and mate lapping: -MSS-SP61 per ANSI 816.34 -Class VI per FCI 70-2 -API 598

TEACHNICAL PARAMETERS

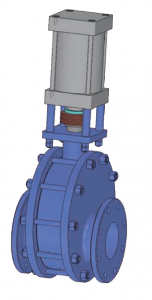

EVT Bulk Material Valve (EMV)

Size: DN15-DN450

Pressure: Class125, Class150, Class300 Body

Material: Carbon Steel, Stainless Steel Actuators: Pneumatic

Configuration

- Pneumatic Actuator

- Double Discs and Seats design

- Bi-direction flow

- Bi-directional seal

FEATURES AND BENEFITS

- Full Port Design

- Designed thickness of valve body compiles with ASME B16.34, Better erosion resistance.

- More packing rings with larger Cross Section ring are used.

- Body seal design uses a combination of the base metal-spiral wound with grafoil.

- Larger and more body bolting: maintain a better bolting load on body seal.

- Many harden treatments for disc and seat are available, Tungsten Carbide Clad, Solid Tungsten Carbide, Stellite Overlay and 440C.

- Seat leakage can meet below specifications by polishing and mate lapping: MSS-SP61 per ANSI 816.34; Class VI per FCI 70-2

- Pneumatic Actuator

- End Connections: Flange per ASTM 816.5 or Wafer type